Stretchable

Strain Sensors

Liquid Wire™ strain sensing technology delivers incredibly precise measurements of material deformation, providing valuable insights for applications in health monitoring, sports performance, wearable technology, and industrial settings where understanding subtle changes is critical.

Linear Gauge Factor

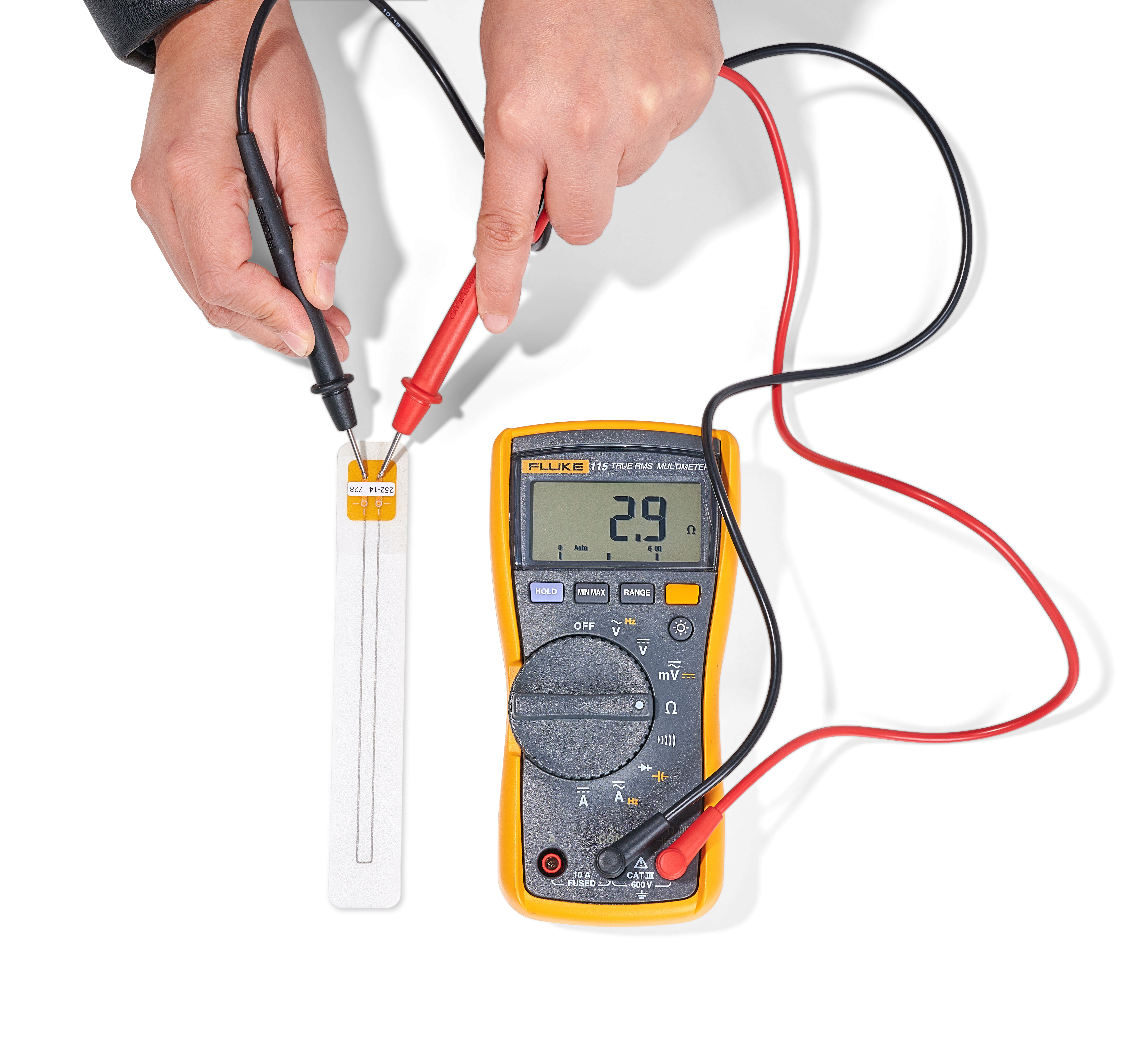

With its highly flexible and stretchable Metal Gel™ circuitry, Liquid Wire™ Stretchable Strain Sensors exhibit a linear change in resistance under strain, enabling them to detect tensile or compressive movement typically outside the realm of measurable.

1 Million Cycles at 30% Elongation Without Performance Degradation

While many strain sensors fail past 5 or 10% strain, Liquid Wire™ sensors can be cycled repeatedly to 30+%. Coupled with a low-cost precision current source, this sensor can detect sub-millimeter changes in length with near-zero hysteresis.

Features of Liquid Wire™ Strain Sensors

Consistent, Linear Gauge Factor

Liquid Wire™ resistive strain sensors deliver precise, linear, and repeatable measurements, making them ideal for applications requiring accurate data under demanding conditions, including repeated stretching, compressing, bending, and twisting.

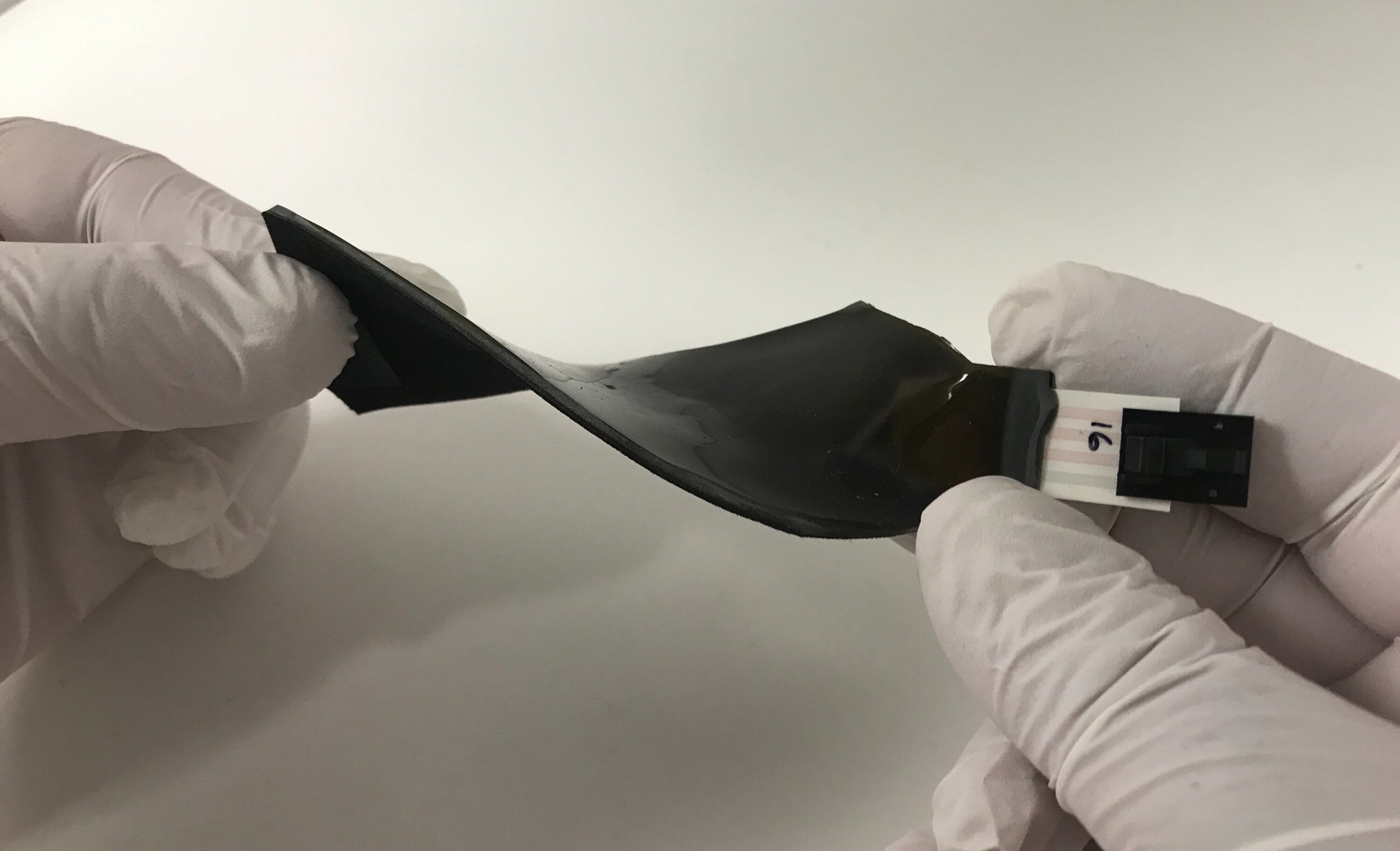

Unmatched Stretch and Sensitivity

Crafted from Metal Gel™, a proprietary liquid metal alloy, and embedded in a robust thermoplastic laminate structure, our strain sensors can stretch and flex without compromising their integrity.

Custom Designs

The Metal Gel™ traces can be designed with fewer or more returns over the same sensing area, adjusting the sensitivity and modulus. We can also design the sensors to lock stretch in certain areas, focusing on detecting strain in specific regions.

Durability Under Extreme Conditions

Designed to endure repeated and extreme strain, our sensors can handle 30% elongation for virtually endless cycles.

Versatile Integration Options

Our strain sensors can be easily attached to a variety of textiles, including fabrics and garments, using methods such as heat pressing or sewing. This versatility allows for seamless integration into different materials, making them suitable for a wide range of applications.

Choose Your Connector

Our proprietary, rugged hard-to-soft connection system allows Liquid Wire sensors to interface seamlessly with existing PCBs, flex components, and microcontrollers. We offer multiple connection options, including:

- Flex Polyimide Board with Copper Contact Pads: For direct soldering.

- Flex Polyimide Board with Wire Leads: Pre-soldered wire leads for easy connection.

- ZIF Connectors: For simple, solder-free connections.

Advanced Connectivity

Moreover, the same Metal Gel™ conductor that measures strain can simultaneously transmit digital data on established protocols like I2C, USB, and SPI. The resistance and impedance changes are easily detectable but have negligible effects on digital signal transmission, ensuring no disruption to the electrical system's function.

Versatile Connection Solutions

Copper Flex

Flex Polyimide Board with Copper Contact Pads.

For direct soldering.

Flex Polyimide Board with Wire Leads

Pre-soldered wire leads for easy connection.

ZIF Connectors

For simple, solder-free connections.

What Can You Do with Liquid Wire’s Strain Sensors?

Wearable Technology

Health and Fitness Monitoring:

Our sensors provide accurate strain measurements that can be used to monitor body movements, including breathing, track fitness activities, and provide valuable health insights.

Comfort and Durability:

Integrated into smart clothing, these sensors offer comfort and long-lasting performance, enhancing the user experience.

.png)

Industrial and Robotic Applications

Dynamic Environments:

In industrial settings, our sensors can monitor strain and position in machinery and equipment, ensuring optimal performance and safety.

Robotic Integration:

Used in robotics, the sensors enhance the precision and control of robotic movements, improving efficiency and effectiveness.

Research and Development

Flexible Research Tools:

Researchers can leverage our sensors in various experimental setups to gather accurate strain data, driving innovation in multiple fields.

Custom Solutions:

Liquid Wire™ offers customizable sensor designs to meet specific research requirements, enabling tailored solutions for advanced applications.

Get the Stretchable Strain Sensor Data Sheet

Download Our Strain Sensor Data Sheet

Explore the Possibilities

Whether for wearable technology, structural health monitoring, or enhancing robotic performance, Liquid Wire™ strain sensors provide the necessary durability, sensitivity, and seamless integration for high-performance environments. Choose Liquid Wire™ strain sensors for superior performance and reliability in your most challenging projects.